Water: Big Challenge with CSP

<Wet-cooling towers (on the left) at Nevada Solar One CSP plant in Boulder City.

September 10, 2010 - The Concentrated Solar Power Yield Optimization Conference & Expo is set for in Denver in October 27-28, 2010, and addressing water scarcity in the sunny arid deserts will be a main topic.

Babul Patel, senior consultant at Nexant Inc., will talk about the cost implication of plant cooling options and how to operate plants effectively under increasingly stringent water restrictions.

A key issue with water use is its cost. In the southwest US people are waking up to the fact that water is a very valuable resource and that it is not convenient to see it evaporate in a cooling process. And itt is getting increasingly difficult to extract ground water for CSP because so many aquifers are in overdraft already.

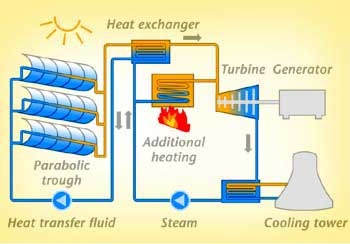

There are two options for cooling the steam cycle in solar thermal power plants:

1. Wet-cooling.

2. Dry-cooling.

Wet-cooling towers, also used by nucear power plants, have mechanical draft systems, fans, to cool water as it evapotares. As much as 92% of all plant water use may go to plant cooling in this system.

Dry-cooling towers use 90% less water. Water is condensed after steam is run through fans. These air-cooled consensers add 5% to plant capital costs. In hot air temperatures power production is reduced, net about 5%. At 90 degrees Fahrenheit ouput is reduced to 95%, while wet-cooling systems remain at 100%. This sytem increases the cost of producing electricity by 10%.

A 250 megawatt (MW) solar thermal plant would use 3500 to 4500 acre-feet per year, while a 250 MW dry-cooled plant would use 300-500 afy. (Renewable Energy workshop by D. E. Ochenreider, March 13, 2010)

The downside of air-cooled condensers is that on hot days they have very poor performance that affects the turbine’s efficiency and output during the time of day when sunlight is stongest and the plant would be normally operating at highest efficiency. In both power tower (such as the Ivanpah Solar Electric Generating System proposal) and parabolic trough technology (for example the Palen Solar Power Project), the condensing temperature from the turbine exhaust is dependent on the ambient conditions. For wet a cooling tower, it is the wet bulb temperature, whereas for the air cooled condenser it is the dry bulb temperature. So on hot days, when market demand for energy is very high, the turbine is operating at reduced capacity and efficiency.

Air-cooling can cost 2.5 times that of mechanical draft cooling towers. The majority of that cost is the total cost of material. A 100-200MW CSP plant cooling tower can occupy as much land as a football field. Such a large surface area has a high material cost. Some innovations are being made on structural improvment, using minimal support structure. "As we learn more about the layout and structure there are some cost savings, but these are miniscule compared to materials costs that are dependent on commodity prices," says Patel.

^Dry-cooling tower for a natural gas power plant at Boulder City, Nevada.

So engineers are looking at all the options. One is hybrid-cooling using a 25% capacity wet cooling tower and 100% capacity dry cooling condenser. In the hybrid type of cooling, part of the turbine steam exhaust is reverted to the wet cooling tower when ambient temperature rises. This option improves efficiency compared to a 100% dry cooling tower, and with little loss of capacity. The wet cooling tower is only used on hot days, so only 10% of the water would be used compared to a wet cooling tower, given that it would only be used for only a few hundred hours a year when the temperature is at a peak. The dry-air cooled condensers experience efficiency losses at around 90 degrees Fahrenheit / 32 degrees Celsius ambient temperature for about 40-60 days a year. This is the time to take advantage of wet cooling.

Organic Rankine cycle (ORC) technologies are another low temperature operating system using an organic compound which uses steam turbine exhaust to vaporize organic fluid that is used in another turbine cycle. It operates at lower temperature, but reduces the cooling load of a combined plant by as much as two-thirds of a conventional system. It takes the steam exhaust from the Rankine cycle and uses that heat to operate an organic fluid. The technology has been used in geothermal plants for years.

In CSP plants, the capacity factor is low, at around 20-25% and the added capital investment for something that is used only a small amount of the time means that the return on investment is not attractive. The solution would improve the overall CSP plant efficiency and would bring down the cooling load of the plant. But Patel warns, "But nobody has actually done this yet, so it is not clear as what the extra cost would be."

Waste water is a viable option that is being looked at for several developments in California and Arizona. It is difficult to tap into, unless the plant is sited near a large community. If the plant is close to a municipal wastewater treatment plant, then the option becomes economical. Beacon Solar Power Project and Imperial Valley Solar Project are both seeking this option by building pipelines.

More and more power plants are being required to have zero water discharge restrictions. Most power plants are tending toward zero water discharge, where they have to treat and re-use water, but this adds significant capital and operating costs. So there is a need for minimizing water consumption.

^Steam from the wet-cooling tower at Nevada Solar One.

Abengoa Mojave Solar Energy Project at Harper Lake

As an example of the stresses being placed on water resources by proposed solar energy projects, the Abengoa Mojave parabolic trough solar thermal project was licensed on September 9, 2010 by the California Energy Commission. It will be a 250-MW plant on private land that is abandoned agricultural land northwest of Barstow, San Bernardino County. The new power plant would use a maximum of 2,160 acre-feet per year of groundwater. At the Centro Water Advisory Committee meeting held 26 October 2009 near Barstow, it was stated that only 870 acre-feet are in production right now. Abengoa bought 11,000 af of water rights in the process of buying the Paul Rankins property.

It will operate using new groundwater wells from Harper Lake Basin, an area that is in critical overdraft, and was water rights adjudicated. A water master regulates use. Abengoa bought several water rights. In a January 2010 status conference, the Energy Commission demanded that Abengoa switch to dry-cooling for this project, or it would nit get approval. But since then, the project has been allowed to continue its plans to use wet-cooling.

The Presiding Members Proposed Decision says:

"Because the project proposes use of well-drawn groundwater for wet cooling, the Applicant and Staff disagreed on whether the project – absent the water conservation measures discussed below–complies with state and Energy Commission policy regarding the use and conservation of water resources. The Applicant determined that the project is compliant with state policy and requires no related mitigation or conservation measures. Staff concluded, however, that water conservation measures as set forth herein, were required in order to make the project comply with state and Energy commission policy. As more fully discussed below regarding LORS compliance, we agree with Staff." (page 360, for pdf see CEC web page)

"Historically, as a result of agricultural development, groundwater consumption exceeded groundwater recharge. Under pre-development conditions (i.e., prior to the 1930s), groundwater discharged to Harper Lake. As agricultural use of the land developed, the groundwater elevation lowered due to pumping and consumption from storage to such a degree that discharge from the regional aquifer to the lakebed no longer occurs. Now, perched water conditions generally exist at approximately 27 to 33 feet below ground surface (bgs) near Harper Lake."

Harper Dry Lake Wetlands nearby is an Area of Critical Environmental Concern, are artificially maintained by the Bureau of Land Management with groundwater pumped from a former irrigation well located on the proposed Beta field of the Abengoa Mojave Solar site.

^Wetlands at Harper Lake.

^American avocet at Harper Lake.

^SEGS 9 and 10 at Harper Lake, next to the proposed Abengoa Mojave facility. To the right are the wet-cooling towers. These plants were built in 1989 and 1990, are now owned by NextEra Energy. They use Los Angeles Aqueduct water.

^The solar field at SEGS Harper Lake.

^Representation of the proposed giant Abengoa Mojave Solar Energy Project next to Harper Dry Lake.